SAM Composites India Pvt. Ltd. are renowned epoxy fiberglass laminate sheet manufacturers with more than 30 years of experience. We supply our strong laminate sheets for a wide scope of applications in the electrical, consumer electronics, energy, aerospace, general manufacturing, automotive, railways and many other industries. Epoxy fiberglass composite is highly useful because of its insulation, strength and heat-resistant properties. But various applications require different combinations of epoxy matrix and fiberglass substrate. Hence, we make different kinds of laminates based on guidelines by different authorities. Besides, we also make them in a customized form to meet our customers’ specific needs.

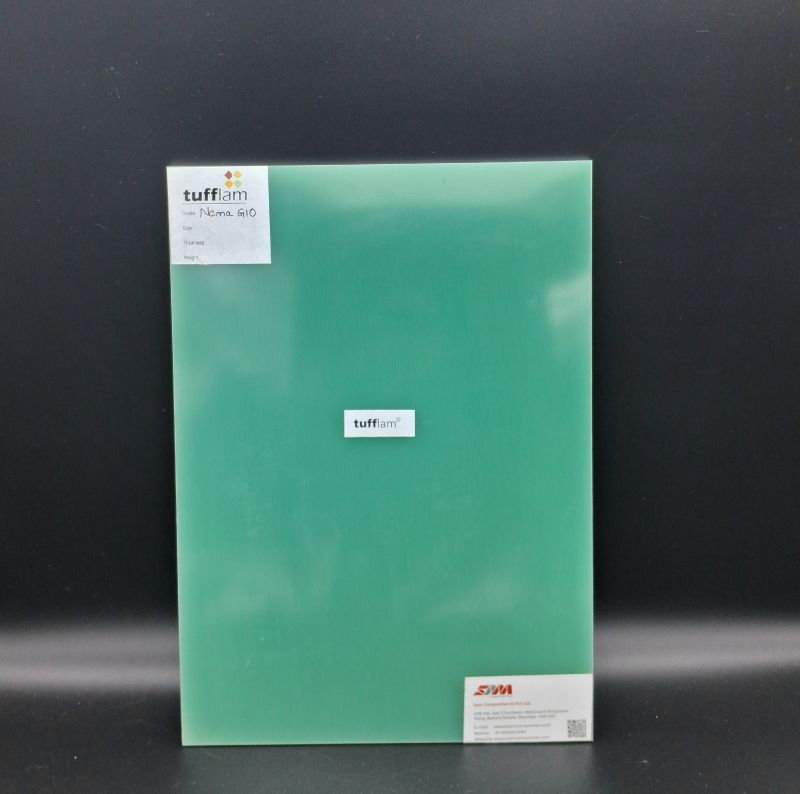

Our epoxy sheets are famous by the brand name ‘Tufflam’. The composite of epoxy and fiberglass is rigid and highly resistant to wear. Our raw materials are sourced from the trusted and certified vendors. We conduct stringent quality tests based on guidelines set by respective authorities. Here are the advantages we provide as epoxy fiberglass laminate sheet manufacturers:

Despite these top rated properties, our sheets remain lightweight and easy to handle. These are made to the standards set by NEMA, UL, ASTM, and IEC and we supply to different requirements the most suitable one from our series.

SAM Composites India Pvt. Ltd. has been a reliable supplier and trader of rigid laminate sheets. Our clients come from some of the most reputable business backgrounds. We maintain excellent quality standards as epoxy fiberglass laminate sheet suppliers. If you choose us, you will get the right sheets as our team assesses your needs in detail before presenting the solution.

| Key Characteristics | Test Method | Units | Values |

|---|---|---|---|

| Mechanical Tensile Strength | ASTM D-638 | psi (MPA) | |

| LW | 40000 (275) | ||

| CW | 32000 (220) | ||

| Flexural Strength | ASTM D-790 | psi | |

| Flatwise | 27000 (186) | ||

| Edgewise | 22000 (152) | ||

| Compressive Strength | ASTM D-695 | psi | |

| Flatwise | 60000 (413) | ||

| Edgewise | 35000 (240) | ||

| Rockwell Hardness | ASTM - D785 | M Scale | M111 |

| Deformation & Shrinkage Cold Flow at 4000 psi | percent | 0.25 |

| Key Characteristics | Test Method | Units | Values |

|---|---|---|---|

| Electric Strength | ASTM D-149 | kV/mm | 16 |

| Dielectric strength perpendicular | ASTM D-149 | V/mil | |

| Short time test | 1/8 in. | 550 | |

| Step by Step test | 1/8 in. | 350 | |

| Impact Strength (Izod) | ASTM D-256 | ft.lb/in | 7 |

| Bonding Strength | ASTM D-229 | lb | 1600 |

| Permittivity | at 1 MHz | 5.4 | |

| Dissipation factor | at 1 MHz | -- | |

| Breakdown Voltage | ASTM D-149 | KV | 45 |

| Comparative Tracking index | ASTM D-695 | CTI | 390 |

| Insulation Resistance | ohm | 2000000 |

| Key Characteristics | Test Method | Units | Values |

|---|---|---|---|

| Specific Gravity | ASTM D-792 | G/cm3 | 1.9 +/- 0.1 |

| Specific Volume | in3 | 14.9 | |

| Thermal Expansion | cm/cm. C | 0.00001 | |

| Thermal conductivity | ASTM D-256 | Cal.cm/s.cm2. C | 0.0007 |

| Specific Heat | cal/g.C | 0.35 - 0.40 | |

| Moisture / Water Absorbtion | ASTM D-570 | % max | 0.1 |

| Temperature Index | NEMA | C | 135 |

| Insulation Class | B | ||

| Flammability | UL 94 | V0 | |

| Convolute Tubing | Yes | ||

| Highlights |

High Mechanical,

Electrical, Electronics

applications. UL94V-0 |

In compliance with RoHS and REACH directives

The information, suggestions, and recommendations provided on our products are based on tests and data that we believe to be accurate. However, it is the sole responsibility of the user to determine the suitability of any material described herein for their intended use, the manner of such use, and whether the use infringes any patents. We make no warranty, expressed or implied, including but not limited to warranties of merchantability or fitness for a particular purpose.

It is important to note that we shall not be liable for any incidental or consequential loss or damage resulting from the use of our products. We strongly recommend that users perform their own tests and evaluations to determine the suitability of our products for their particular purposes.

If you are interested in our products, please feel free to contact us!or send email to us!Email Address:sales@samcomposites.com

If you are interested in our products, please feel free to contact us!

Contact us